Acuity Triton

Revolutionary new AQUAFUZE ink with the Acuity Triton Harness elemental power

The Acuity Triton, powered by AQUAFUZE ink technology, is a revolutionary new roll-fed printer platform. It meets a multitude of market requirements by combining the benefits of LED UV and water-based inkjet technologies:

- It has low energy, low temperature drying compared to traditional water-based print systems.

- It provides excellent adhesion to a wide range of media without the need for a pre-coat primer or optimiser.

- Prints have a thin film that is scratch-resistant and do not require a top coat.

- Prints are low-odour, safety compliant, Greenguard approved and GHS label-free.

- The technology offers excellent jetting stability as a result of reduced nozzle blocking due to the low temperature drying.

- Instant cutting and lamination is possible, due to the make up of the water-based UV AQUAFUZE ink technology

The brand new Acuity Triton is the first printer to benefit from AQUAFUZE ink technology

The Acuity Triton is a 1.6 m wide printer that boasts a unique print/dry process that has been specifically designed and perfectly optimised for AQUAFUZE ink technology to ensure it always delivers excellent print results whilst maximising production efficiency.

Acuity Triton key features

- 1.6 m wide printer

- A unique print/dry process

- Optimised for AQUAFUZE ink technology

- Rapid startup with no excessive heat build-up

- Ultra-reliable low-temperature cure

- Low energy consumption

Drawing on more than 70 years of ink development history, Fujifilm is proud to introduce AQUAFUZE – a water-based LED UV inkjet ink built on a unique new photopolymer and an intelligent dispersion.

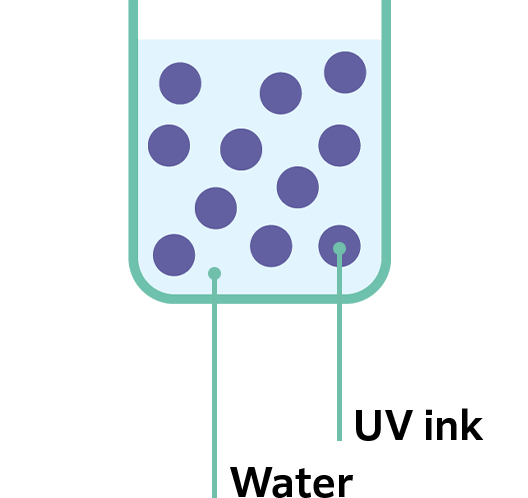

AQUAFUZE inkjet ink is formulated from Fujifilm’s proprietary technology for stable water dispersion of photopolymers. Fujifilm has applied its original synthesis technology for highly functional materials and particle dispersions to create RxD dispersions. Based on this revolutionary dispersion, Fujifilm has developed a new UV-curable aqueous ink by combining the formulation technologies of both water-based and UV-curable inks.

A breakthrough in ink technology

Water-based UV inkjet inks are notoriously difficult to produce as traditional UV oligomers and monomers break down and agglomerate when in prolonged contact with a water-based solution.

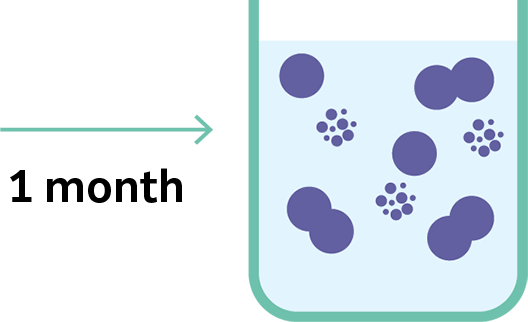

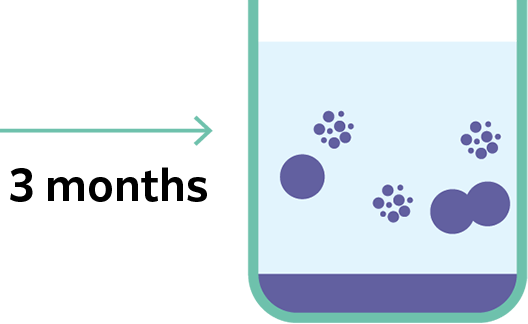

This results in poor prints and head blockages:

|

|

|

|

| After 1 month, the UV ink dispersion starts to break down and also agglomerate forming larger clumps of UV ink. | After 3 months, the larger agglomerates have started to settle out at the bottom of the ink container. | Leads to satellites, deviations, blocked nozzles = Poor print quality |

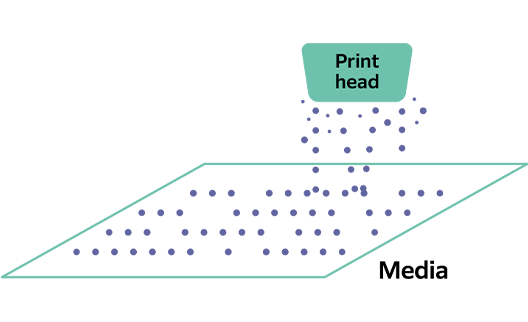

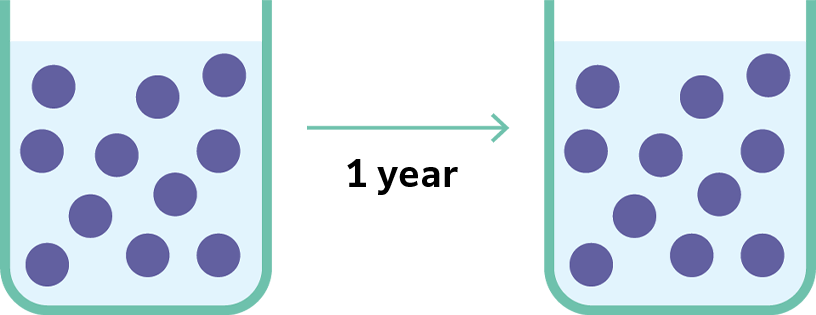

Water-based UV curable inks formulated using Fujifilm’s AQUAFUZE technology:

|

Even drop placement and stability, uniform jetting velocity = Good print quality |  |

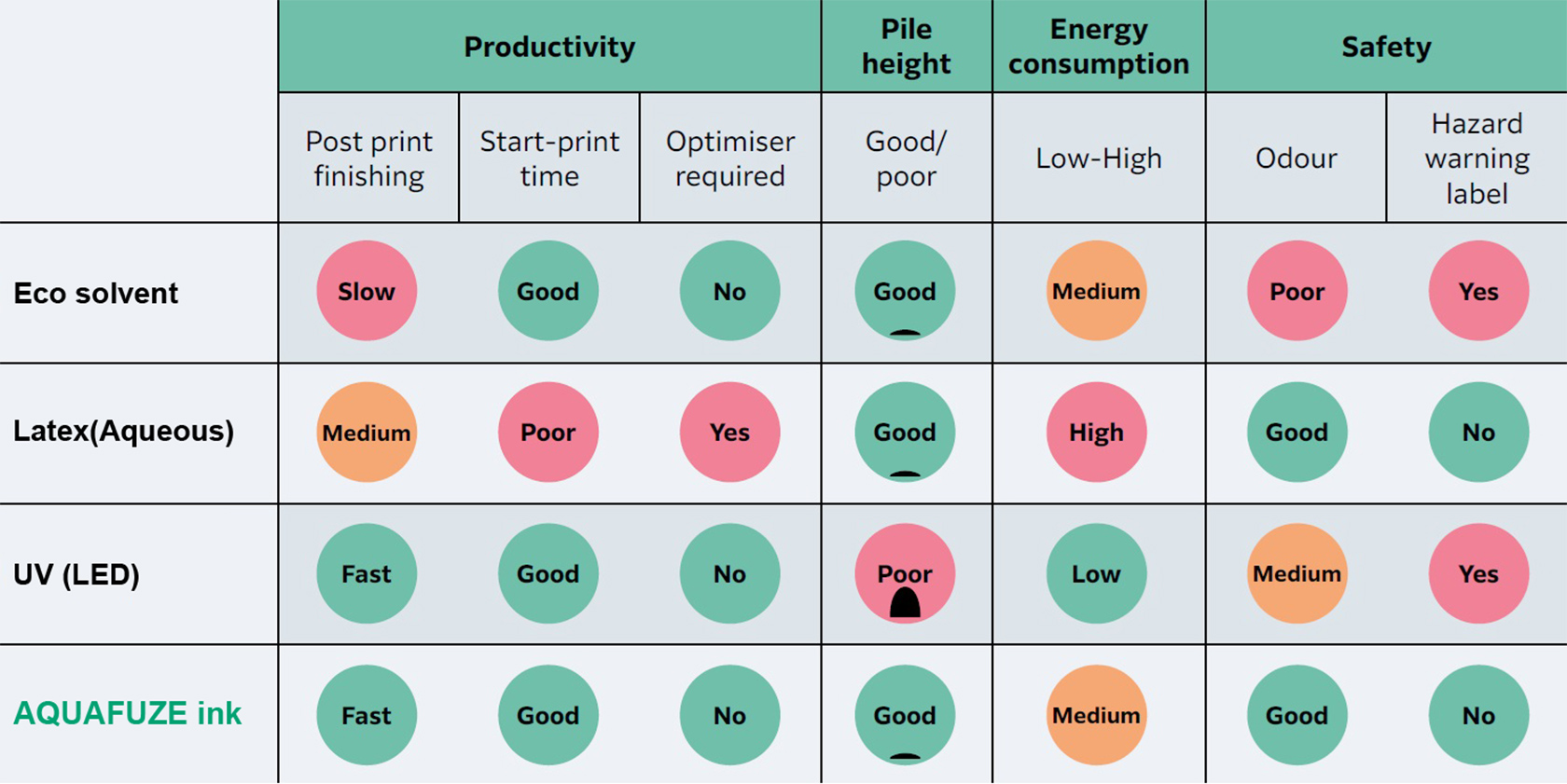

Water-based UV has long been regarded as the ultimate inkjet ink technology combining the benefits of LED UV curing with those of water-based as the table below shows:

Testing carried out on a limited number of machines. Fujifilm shall not be liable for technical errors contained in this table.

AQUAFUZE inks have multiple benefits for more than just sign printers

Robust ink filmEnjoy benefits of printing with UV |

‘Soft feel’ low buildCustomers will love the feel |

|||||

Low heatUse more heat sensitive media |

Wide application rangeNo need for optimisers |

|||||

More production opportunitiesInstant cutting and lamination |

|

Acuity Triton Key Specification

| Resolution | Up to 1,200 x 2,400 dpi | |

| Productivity | Draft (1,200 x 6,00 dpi): 17.2 m2/h High speed (1,200 x 1,200 dpi): 15.3 m2/h Production (1,200 x 1,200 dpi): 11.5 m2/h Quality (1,200 x 1,800 dpi): 9.4 m2/h High quality (1,200 x 2,400 dpi): 5.8 m2/h |

|

| Ink Type | AQUAFUZETM water-based UV ink | |

| Ink drop size range | 3.4 - 10.6pl (operator selectable) | |

| Ink colour | 4 Colors (Cyan, Magenta, Yellow, Black) / 1 litre pouch | |

| Ink Certification | GREENGUARD Gold certified - category Wallpaper AgBB 2024 French VOC and CMR-regulation: Class A+ Belgian VOC regulation |

|

| Maximum printable size | Width: 1,615 mm, Length: 1,500 m | |

| Media size | Roll media width; 500 mm - 1,625 mm Roll media weight: 30 kg or less Thickness: 1.0 mm or less Core diameter: 2 or 3 inches |

|

| Interface | Gb-Ethernet (1000BASE-T) | |

| Power Supply | Voltage: AC 100V/ 120V ± 10% / AC 200V/ 240V ± 10%, Frequency: 50/ 60 Hz ±1 Hz | |

| Power Consumption | Power off: 20W or less Standby: 240W or less Operating: 1.4kW or less (peak: 2.7kW) |

|

| Dimension | 2,770 mm x 8,95 mm x 1,611 mm (with ink pack adapters mounted) | |

| Weight | 186 kg (Printer body: 146 kg, Stand: 32 kg, Winder: 8 kg) | |

| RIP Connection | VerteLith for Fujifilm (bundled) and other RIPs compatible | |

| Enviromental conditions | Printer operation: temperature: 20oC / 32oC; humidity 40% / 60% RH - no condensing Accuracy guaranteed: temperature: 22oC / 30oC; humidity 40% / 60% RH - no condensing |

Sales |

Service |

|||

|---|---|---|---|---|

|

Sergio Rebronja |

Matej Meterc | Phone: +386 (0)80 35 65 | ||

| Key Account Manager | COO | Support Portal: podpora.uni-biro.si | ||

| e-mail: servis@uni-biro.si | ||||

| Phone: +386 (0)40 196 049 | Phone: +386 (0)1 530 27 06 | |||

| e-mail: sergio@uni-biro.si | e-mail: matej.meterc@uni-biro.si |